Services

Products and services offered by “Ülkər-7”

Alarm and monitoring system (AMS)

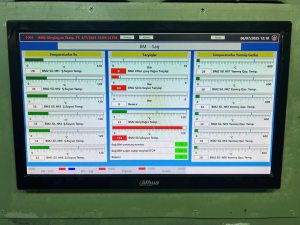

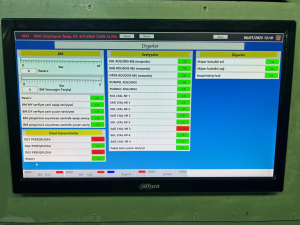

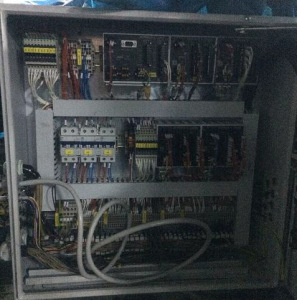

Alarm and monitoring system consists of a central computer with a touch screen, specially developed software (U7-software), stations that collect signals from various sensors, convert them into standard signals, and isolate them, connecting blocks, sensors, and a power supply with high stability and input-output isolation

The central computer screen displays the stations connected to it and the 32 digital and 16 analog signals coming from each station separately. The name of each signal can be read by touching it on the screen or by clicking the cursor on the signal with the trackball. In addition, there is a list of alarms in an emergency (alarm list), system errors (errors), accident history (history), a RESET button to turn off the sound signal and a button to turn off the computer

The background of signals in normal condition is green, the background of signals in warning condition is yellow, and the background of signals in emergency condition is red and flashing. It is possible to temporarily mute signals coming from sensors that are out of order or giving false signals. In this case, the background of those signals is blue and they do not give an audible signal

The central computer is usually designed for the Central Control Panel. On ships without a Central Control Panel, it can be installed in a suitable place in the engine room, protected from water flow and mechanical damage

A second computer can be connected to the central computer, which doubles it, and it is possible to install this computer on the captain’s bridge. The second computer will repeat all the functions of the central computer, but it will not be possible to turn off the sound signals. Because before turning off the sound signals, the mechanic must investigate the causes of the accident, and for this it must be on the Central Control Panel

Up to 4 stations can be connected to the central computer, which means that 136 digital and 64 analog signals can be monitored simultaneously

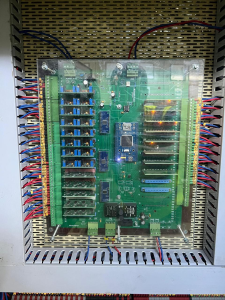

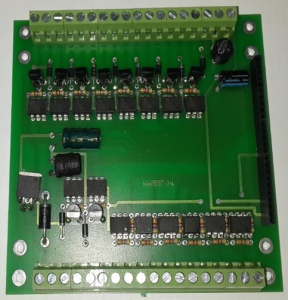

Alarm and monitoring system station consists of a high-stability, input-output isolation power supply that feeds the digital and analog signal converter blocks and sensors, digital and analog signal converter blocks, and a motherboard that performs a connecting function

The station has 8 digital signal converter blocks and 8 analog signal converter blocks. Each block is in the form of a board and converts two analog or four digital signals into a standard signal

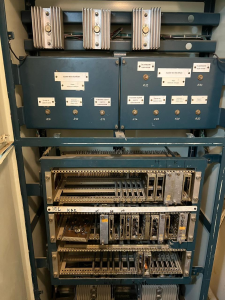

Dynamic Positioning System

Technical equipment complex of the system.

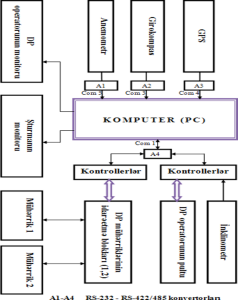

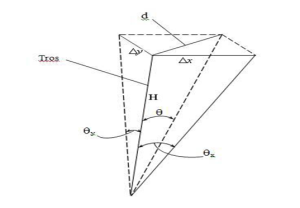

The corresponding technical means of the Dynamic Positioning System of the Ali Amirov ship form a complex. All control and management devices are integrated into the system computer. It includes:

The system’s input controllers (two MicroPc type controllers from Fastwel). The input controllers are connected to the computer’s COM1 port via the RS 485 standard of the ADAM 4520 converter.

Output controllers of the system (two MicroPc type controllers of Fastwel company). Output controllers are connected to the COM1 port of the computer by the RS 485 standard of the ADAM 4520 converter. The output parameters of the system are the control signals of the shuttles.

Anemometer device

Gyrocompass device

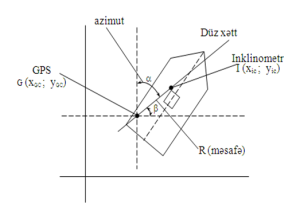

GPS device

Inclinometers

Central system computer

System Software:

The software of the Dynamic Stabilization system of the Ali Amirov vessel consists of a complex of programs. It includes:

Input controller software;

Output controller software;

DP operator control and management software;

Drill operator control software;

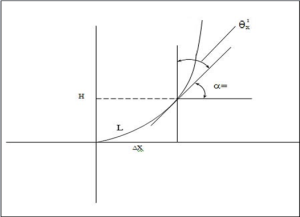

Removal of the vessel to the drilling point. The vessel can be removed to the drilling point in two ways:

By manual control.

Automatically.

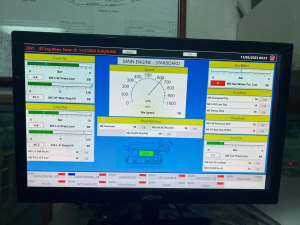

Data is continuously received and indicated from each of the devices of the Dynamic Stabilization system in all modes

Operational position of the ship:

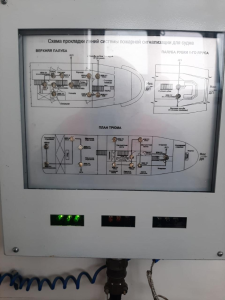

The operational schematic position of the ship is given inside the red square in the center of the screen. Here, the letter N indicates the direction of north. The position of the ship relative to the north according to the course is determined after each gyrocompass query and the schematic ship image is redrawn.

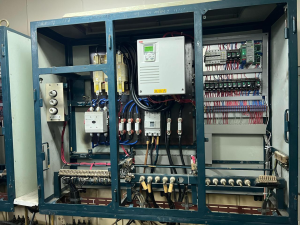

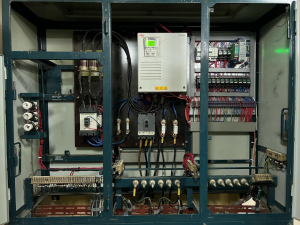

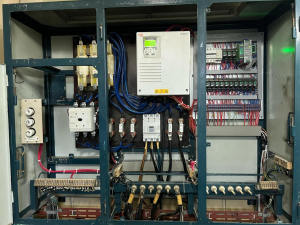

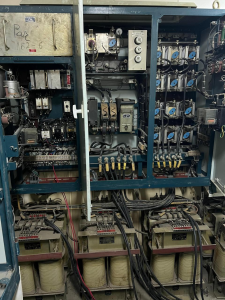

Unified software control unit for diesel generator control, protection and alarm system

This block provides engine start-up, operation, shutdown (normal and emergency) and protection against accidents in three modes:

1) Automatic

2) Semi-automatic

3) Manual control

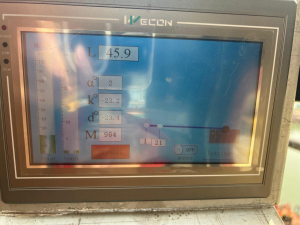

The block measures the number of engine revolutions and transmits them to the 4×7 segment display panel, and also creates 4 threshold limits to ensure normal operation in automatic mode.

1) 300 rpm. – pre-shuts off the lubrication pump

2) 600 rpm. – the engine switches to normal operation

3) 700 rpm. – eliminates false and short-term shutdowns

4) 820 rpm. – keeps the engine from overspeeding.

These threshold limits are given for engines with a revolution count of 750. If the engine has a different revolution count, it is possible to change the threshold limits by entering the menu. The unit also provides automatic control of the pre-lubrication pump in automatic mode. It is possible to obtain information about the engine mode, buttons, sensors and valve status through 10 light-emitting diodes located on the front panel of the unit.

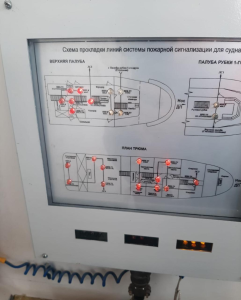

Fire alarm system

In 1995, the NID-38 type smoke detectors on ships were repaired for the first time, test and inspection stands for checking smoke and heat detectors were assembled at the enterprise and in 1997, it received a certificate of recognition from the RDG Register for the first time. Therefore, in 1998-2002, our enterprise installed equipment in accordance with the signaling and Solos requirements at the ADXDG.

Fire alarm systems of the following brands were repaired: SPSP-20, SALVICO, C-300 of Swedish manufacture

BVZ, BKZ of German manufacture

Kristal, TOL-1050, DELFIN of Russian manufacture

MK-513 of Danish manufacture

UCPP-10, UCPP-20, TSPP of Polish manufacture

SFDU-77 of Norwegian manufacture

47V of Yugoslav manufacture

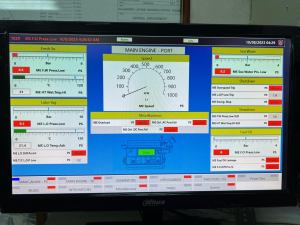

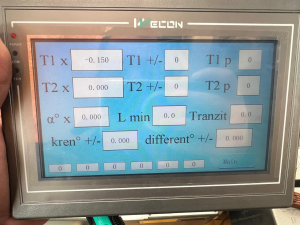

Integrated software control unit for the main engine control, protection and alarm system

This block is designed for 5 types of revolution sensors that can be installed on the main and auxiliary engines:

1. Tachogenerator

2. Inductive sensor

3. Pnp type electronic sensor

4. Npn type electronic sensor

5. Differential sensor

The block measures the number of engine revolutions and transmits it to the 4×7 segment display panel, and

creates 4 threshold limits to ensure normal operation in automatic mode

1. 300 rpm. – pre-shuts off the lubrication pump

2. 600 rpm. – the engine switches to normal operation

3. 850 rpm. – eliminates false and short-term shutdowns.

4. 1180 rpm. – keeps the engine from overspeeding.

These threshold limits are given for engines with a cycle count of 1000. If the engine has a different cycle count, it is possible to change the threshold limits from the menu.

The block has both analog and digital outputs. The analog output can be set to either 1-5 mA or 4-20 mA, allowing up to 20 indicating devices to be connected at a distance of up to 500 m. The digital output can be used to connect both digital indicating devices and various types of meters.

Display and electronic measuring unit of the crane's lifting, slewing and axis control system

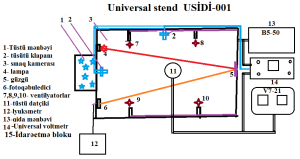

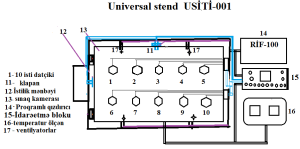

A new, modern version of the OGP systems measuring and limiting load, axis and moment on 40-ton and 100-ton crane ships has been designed, developed and prepared, a software-based control system displaying information on a large-screen display has been assembled, installed and put into operation on Atlet and Shirvan type ships. A universal portable stand has been assembled for checking the electronic boards of the control system of crane ships.

A universal portable stand has been assembled for checking electronic boards of crane vessel control systems

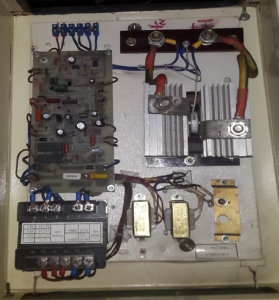

Synchronous generator induction block

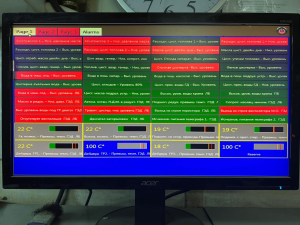

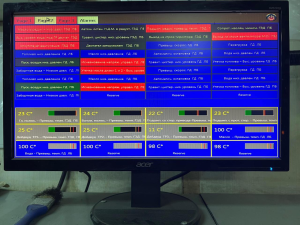

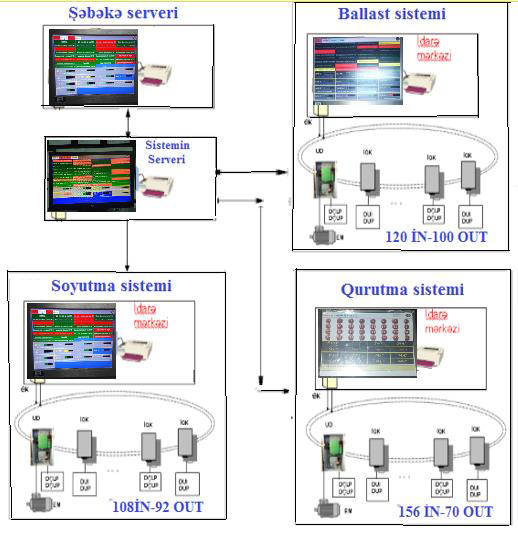

Ballast, drying and cooling system

A centralized network system for ballast, drying and cooling systems has been designed, the software of the system with 120 inputs-100 outputs for the ballast system, 156 inputs-70 outputs for the drying system, 108 inputs-92 outputs for the cooling system has been developed, a drying system has been installed on the Dagestan type ferry, a remote control system has been created, the ability to start the system, fully monitor and control the work by touching the screen on the monitor on the central control panel has been provided

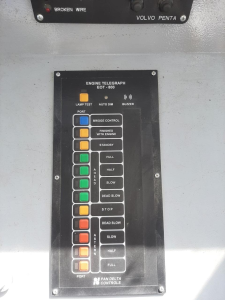

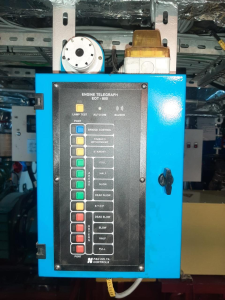

Machine Telegraph and its control unit

Modernization of 40-ton crane on athlete-type ships

Modernization of papillonage winches on the ship of Engineer Balarza Mammadov